What Are Miscellaneous Metals?

What Are Miscellaneous Metals in Construction?

Understanding the Metal Components That Help You Finish the Job

You’ve probably seen “miscellaneous metals” listed in a bid or plan set—and if you're like most builders or project managers, you've also asked: What exactly does that include?

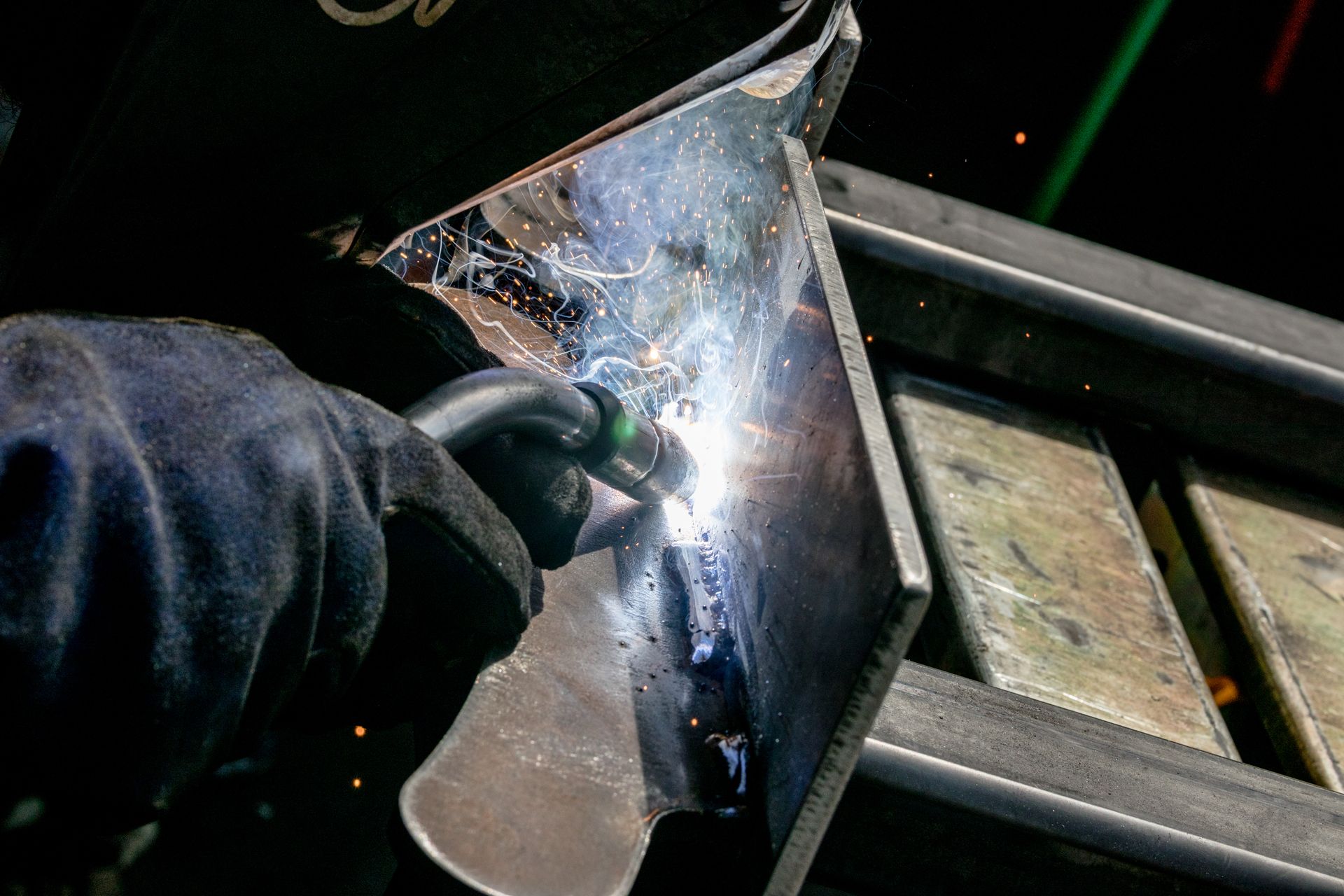

At Top Peak Welding, we handle the entire miscellaneous metals scope so you don’t have to chase multiple subs for stairs, railings, or roof access components. These parts might seem small compared to structural steel, but they play a big role in safety, access, and code compliance.

How Miscellaneous Metals Differ from Other Types of Metalwork

In construction, there are different categories of metal work depending on what the component does, not just what it’s made of. Miscellaneous metals are often confused with structural steel or decorative metals, but they serve a distinct purpose.

Structural steel includes beams, columns, and joists—components that make up the building’s main load-bearing system. These are designed and installed early in the project by structural steel contractors.

Miscellaneous metals are smaller, functional metal items that are not part of the structural frame but are still required to complete the building. They often support access, safety, or equipment, not the structure itself.

Architectural or ornamental metals are typically decorative or design-driven and don’t serve a structural or safety-critical purpose. They’re often pre-engineered or decorative add-ons.

What sets miscellaneous metals apart is how they’re used: they’re custom-fabricated for specific project conditions, built to meet codes like IBC or OSHA, and usually installed during the final stages of construction.

What’s Covered Under Miscellaneous Metals?

The miscellaneous metals scope includes a wide range of job-specific steel and aluminum components that support how people move through, maintain, or use a space. These elements don’t carry the building—they complete it. While they’re still functional, they aren’t structural and usually are needed in the final quarter of the building process, with the exception of steel stair frames.

Typical examples include:

- Metal stairs: Complete stair systems with steel stringers and concrete or pan treads, built to site dimensions. As mentioned above, depending on the style of building, these may be installed at the structural phase to be used by contractors during construction.

- Handrails and guardrails: Interior or exterior, fabricated to meet safety and accessibility codes.

- Dumpster gates: Steel-framed gates mounted on posts or walls to hide dumpsters or protect trash enclosures.

- Rooftop ladders: Wall-mounted or freestanding, with or without cages, for ground-to-roof or roof-to-roof access.

- RTU support frames: Custom welded frames that support the weight of rooftop HVAC or mechanical equipment.

- Awnings and canopies: Designed as structural frames for overhead coverage, not just for looks.

Each of these is custom-sized, fabricated off-site, and installed after finishes are underway. They may be outlined on blueprints or site plans with specifications about materials, sizes, and lengths. They require coordination with field conditions and final layout—not something structural steel contractors typically handle.

What Are The Material Types Used in Miscellaneous Metals

Most of the components for this fabrication fall into one of three material categories: carbon steel, aluminum, or stainless steel, depending on the project's requirements.

Carbon steel is very common. It’s strong, weldable, and versatile—perfect for stairs, handrails, dumpster gates, and RTU frames. We can offer raw, primed, painted, or hot-dip galvanized finishes depending on exposure.

Aluminum is lighter and corrosion-resistant. It’s ideal for rooftop ladders, handrails, signage frames, and fencing or awnings where weight reduction or weather resistance matters.

Stainless steel is less common due to cost, but it’s used in high-exposure environments, medical settings, or for high-end architectural details.

If you’re unsure which material best fits your project, we’ll walk you through the options and recommend the right one for strength, finish, and longevity.

Why Do The Misc Metals Scope Matter?

You may not notice these components at first, but you will if they’re late or done wrong.

Rails and gates that don’t meet spacing codes? That’s a failed inspection. A rooftop ladder that’s missing anchoring or clearance? That’s a safety issue. Even small delays in this scope can slow down final turnover or occupancy.

That’s why we approach every misc. metals job with the same care we give to core steel fabrication. You can’t finish a job with metal fabrication that hasn’t been installed or is incomplete. These components are part of your success, not afterthoughts.

Why Do You Need a Miscellaneous Metals Fabricator?

Not every local welder or contractor can build code-compliant metal stairs, gates, or RTU frames. We specialize in this scope because it requires precision and fast adaptation.

Our team knows how to:

- Read architectural and structural plans, blueprints, and CAD drawings

- Take accurate field measurements

- Apply finishes like galvanizing, painting, or powder coating

- Handle final-stage installation around finished surfaces

- Ensure ADA handrails, OSHA ladders, and welded joints pass inspection

We’ll work directly with your superintendent, project manager, or GC to walk the site, coordinate timing, and make sure everything fits before we fabricate.

FAQs

What’s typically included in the miscellaneous metals bid?

Every building is different but some of the most common bids include stairs, rails, driveway gates, dumpster gates, roof ladders, and steel frames, not covered under structural steel. We also fabricate mounting brackets, awning supports, and job-specific welded elements.

Do miscellaneous metal items need to meet code?

Yes. Handrails, ladders, and other safety components must meet local IBC and OSHA standards. We build everything to pass inspection the first time.

Can you work from sketches or on-site conditions?

Absolutely. If you don’t have full shop drawings, we’ll verify in the field and create what’s needed. Fast turnaround is part of the service.

What kind of finishes do you offer?

Most exterior pieces are hot-dip galvanized or powder-coated for rust protection. Interior items can be painted, primed, or left raw depending on use.

We’ll Take Care of the Misc Metals

If you're managing a commercial project and need custom-fabricated stairs, gates, or railings, reach out. We'll walk the site, coordinate with your team, and get everything built to spec and on time.

Contact Top Peak Welding to request a quote or send us your plans.