AWS vs AISC Certifications: The Standards Behind Safe Metal Fabrication

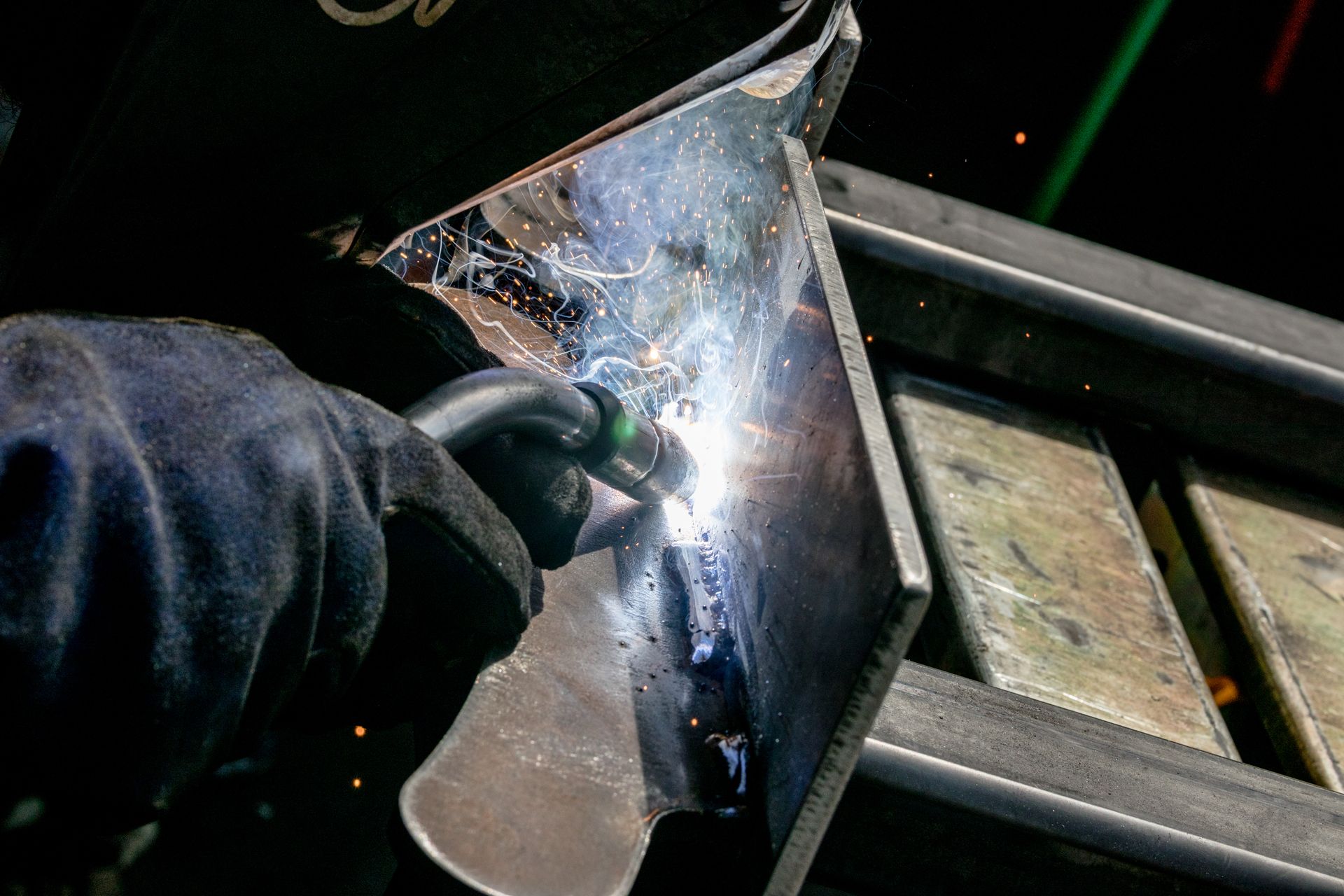

Safety is a term often thrown around within the metal fabrication industry. But for welding shops that operate under recognized certifications, safety isn’t just a promise, it’s a measurable standard. In the US, many metal fabrications are expected to withstand daily foot traffic, wind loads, and years of continued use. If a weld fails on a commercial stair system or structural support, it turns into a safety hazard and a potentially serious legal liability. That’s why certifications matter.

In the US, two of the most recognized standards governing welding and structural fabrication are those set by the American Welding Society (AWS) and the American Institute of Steel Construction (AISC). Understanding the difference between AWS and AISC puts you one step closer to ensuring outstanding results for your project.

What Is the Difference Between AWS and AISC Certifications?

While AWS and AISC have the same goal of ensuring safety and structural integrity, they have different standards and focus on certifications. Later, however, you’ll find that both standards can be used in tandem to achieve fabrication excellence.

Broadly speaking, an AWS Certification tells you that a welder is proficient in specific welding processes and materials. An AWS Certified Welder (CW) has passed performance-based tests, and a certified inspector has confirmed that the welder’s work meets industry codes. Most AWS certifications are focused on the individuals or welders themselves, and not the companies.

Important nuance: AWS certification doesn’t automatically mean that a welder can work on any type of fabrication or structural project. When a welder takes a performance-based test, the test is conducted in line with a designated standard, usually AWS D1.1 (Structural Welding Code - Steel) for structural steel work. Different codes apply to different materials, such as aluminum (D1.2), stainless steel (D1.6), and sheet steel (D1.3). If the project needs load-bearing structural steel for commercial stairs, mezzanines, or supports for awnings, you need welders qualified under AWS D1.1 standards.

Meanwhile, an AISC certification focuses on the company’s entire fabrication operation. It basically answers the question, “Can this welding shop consistently fabricate things like stairs and railings following the required standards every time?” An AISC-certified welding shop ensures that every job is done right by having quality management processes, tracking welder qualifications, following inspection and testing procedures, and performing internal audits to catch any issues early.

AWS vs AISC: Quick Comparison Table

| Feature / Focus | AWS Certification | AISC Certification |

|---|---|---|

| Who It Certifies | Individual welders (as well as welding inspectors, supervisors, and engineers) | The entire fabrication shop |

| Purpose | Ensures a welder can produce quality welds according to a specific code | Ensures the shop consistently produces compliant structural fabrications |

| Typical Standards / Codes | AWS D1 Series (structural welding codes for steel, aluminum, stainless steel, and sheet steel) | Mainly structural steel standards; company-level quality management |

| Scope of Testing | Performance-based tests | Audit of quality management systems |

| Ideal For | Projects that need certified welds on stairs, awnings, gates, etc. | Larger or repeated structural projects where consistency and inspection are crucial |

High-Stakes Welding Projects That Need AWS Certification

One of the most obvious ways to tell if you need an AWS-certified welder is to check the paperwork. Engineers may reference AWS codes to ensure code compliance, and so hiring AWS-certified welders can help you meet the exact rules required by such codes.

Additionally, there are certain projects where AWS-certified welders are essential. In these projects, safety and code compliance are non-negotiables:

Commercial Stairs and Guardrails

Steel stairs and guardrails are load-bearing, and an AWS-certified welder ensures they meet strength, height, spacing, and load requirements. Our team of welders ensures your stairs and railings are also free of cracks or defects.

Metal Awnings and Canopies

Depending on the location, these structures must withstand wind loads, snow accumulation, or seismic activity. Certified welders can produce welds with connections that perform well under real-world stress.

Commercial Gates

Sliding or swing gates are often heavy, and they also experience repetitive motion stress. AWS-qualified welders can reinforce high-stress areas, prevent cracking at corners and joints, and properly weld hinge connections that prevent the sagging of gates.

Mezzanines

If mezzanines will be used to support storage loads, heavy machinery, and personnel, they fall under strict building codes like the OSHA safety requirements and the International Building Code (IBC). When welding is involved, it’s often governed by AWS D1.1.

Welding for Large Fabrication Projects

For large and complex structural steel projects, you’re not just looking for skill but also consistency. You may find that many welding shops in the US employ AWS-certified welders, but not all shops carry an AISC certification. Having both may be a marker of a higher level of capability and process control. This tells you that you can trust the welders (individually) and the entire company to handle engineer-reviewed and code-driven work.

However, this doesn’t mean that non-AISC shops can’t produce quality work. Many do, especially for non-structural or smaller-scale projects. But when inspection-heavy work and load-bearing systems are involved, an AISC-certified shop offers an extra level of assurance through a rigorous quality control system and organized documentation.

Work with Certified Welders for Your Project

In commercial settings, our team understands that metal fabrication is about responsibility, not just appearance. Building stairs that support daily foot traffic, handrails that hold steady under pressure, and gates that operate safely for years—these are some of the real-world outcomes our team is committed to achieving. Our certified welders bring proven experience, skill, and code-based training, reducing delays, costly reworks, or liability issues for your project. By choosing certified professionals, you’re making a smart investment in doing the job right the first time.